Plastics have become indispensable in the manufacturing and engineering industries, revolutionizing how industrial equipment is built and maintained. From their diverse range of properties to their incredible versatility, plastics are an innovative solution aiding the performance, durability, and efficiency of industrial machinery. This post explores the types of plastic materials used, their inherent advantages, and how they’re used within industrial equipment.

Types of Plastics Used

Industrial equipment manufacturers rely on several types of plastics due to their unique characteristics. Polyvinyl chloride (PVC) is a popular choice thanks to its exceptional resistance to chemicals and flexibility. High-density polyethylene (HDPE) is another favorite because of its strength-to-density ratio, making it lightweight yet durable. Polycarbonate is often favored for its transparency and shatter resistance, which are critical elements for equipment requiring visibility without compromising safety. Other materials like PTFE (polytetrafluoroethylene), also known as Teflon, are heavily utilized in cases requiring low friction and high resistance to heat.

Advantages of Using Plastics

Plastics offer a wealth of advantages to the industrial sector, contributing to their widespread application. One significant benefit is their cost-effectiveness. Plastics are generally less expensive than metals, allowing manufacturers to reduce production costs without sacrificing quality. Durability is another key factor—plastics are often resistant to corrosion, wear, and impact, making them ideal for demanding environments. Chemical resistance is particularly valuable in industries working with corrosive substances, where materials like PVC can withstand harsh chemicals over long periods. Their lightweight nature also makes plastics easier to transport and install, adding to overall efficiency.

Another competitive edge plastics provide is their versatility. Manufacturers can mold plastics into complex shapes to create custom components and equipment, a crucial element for projects requiring specialized designs. Additionally, certain plastics, such as PTFE, boast excellent thermal stability, enabling them to function in high-temperature applications where conventional materials might fail.

Applications in Industrial Equipment

The use of plastic materials in industrial equipment spans a vast range of applications. For example, gas regulators often incorporate plastics for their ability to handle pressure while maintaining chemical resistance. The smooth surfaces of PTFE components reduce friction and ensure precise gas flow, which is essential for the safe and effective control of various gases in industrial processes. Of course, plastic can wear with time, so it’s crucial to know how to make sure your gas regulator is accurate, but these plastics can still perform their job for many years without issue. Plastic is also integral in conveyor belt components due to its lightweight and impact-resistant properties. HDPE and ABS (acrylonitrile butadiene styrene), for instance, are frequently used to create belts or rollers that require durability and smooth operation.

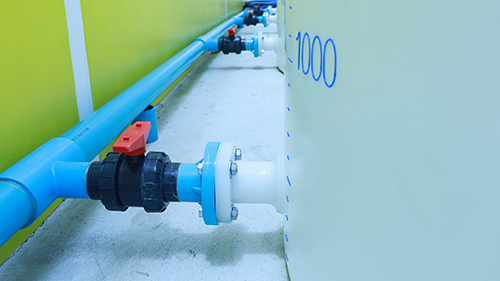

Another notable example is storage tanks used in chemical processing facilities. Plastics like PVC and HDPE are chosen to construct these tanks because of their impressive resistance to corrosion, even when exposed to strong acids or alkalis. Bearings, seals, and gears made from plastics further demonstrate how pervasive and critical these materials have become. Their low friction and high wear resistance ensure extended equipment lifespan and operational efficiency.

Be the first to comment